Precision Gear Reducer

(Also known as Precision Gearbox / Planetary Gear Reducer / Servo Gear Reducer)

Precision Gear Reducer is a high-accuracy transmission device engineered to deliver smooth, stable, and efficient torque reduction for automation systems, robotics, CNC machinery, packaging equipment, and advanced industrial applications. It uses precisely machined gears and optimized gear-mesh geometry to achieve low backlash, high torque density, and excellent positioning accuracy, ensuring reliable motion control and consistent performance even under continuous heavy loads.

Built with high-quality materials and a rigid housing, the reducer provides a long service life, minimal wear, and strong resistance to vibration and impact. Its compact, lightweight design allows easy integration into limited spaces while maintaining high efficiency and quiet operation. Multiple gear ratios and mounting options support flexible configuration for various industrial machines and motion control systems.

Precision Gear Reducer is ideal for robot arms, semiconductor equipment, automated production lines, inspection systems, and high-performance machinery that require accurate speed reduction, improved repeatability, enhanced stability, and dependable precision in modern smart manufacturing environments.

Working Principle

Input Rotation: Motor or drive system provides rotational power to the reducer’s input shaft.

Gear Reduction: An internal planetary or helical gear train reduces speed by the gear ratio (e.g., 3:1, 10:1, 100:1).

Torque Multiplication: As speed decreases, torque increases proportionally at the output shaft.

High Precision Motion Output: The precision-ground gears and low-backlash design ensure exact positioning and smooth motion.

Key Features

High Precision: Backlash as low as ≤1 arc-min for servo-grade models.

High Efficiency: Transmission efficiency up to 97–99%.

High Torque Density: Compact size with powerful output torque.

Smooth and Quiet Operation: Helical gear designs reduce vibration and noise.

Durable Construction: Alloy steel gears and hardened housings ensure long service life.

Mounting Versatility: Compatible with servo, stepper, and AC motors.

Common Types of Precision Gear Reducers

Type

Description

Typical Application

Planetary Gear Reducer

Uses sun, planet, and ring gears for balanced load and compact size

Servo drives, robotics, automation

Helical Gear Reducer

Uses angled teeth for smoother and quieter motion

CNC machines, packaging lines

Right Angle Gear Reducer

Includes bevel or hypoid gears for 90° power transfer

Space-saving assemblies

Spur Gear Reducer

Simple design with straight gears

Light-duty motion systems

Harmonic Drive (Strain Wave)

Flexible spline design for ultra-low backlash

Robotics, precision positioning

Applications

Industrial Robots and Automation Systems

CNC Machining Centers and Lathes

Conveyor Drives and Pick-and-Place Units

Packaging, Printing, and Semiconductor Equipment

Aerospace and Optical Equipment

Advantages

Increases motor torque while maintaining accuracy.

Reduces mechanical vibration and improves system stability.

Compact, space-efficient design for modern automation.

Extends motor lifespan by reducing load stress.

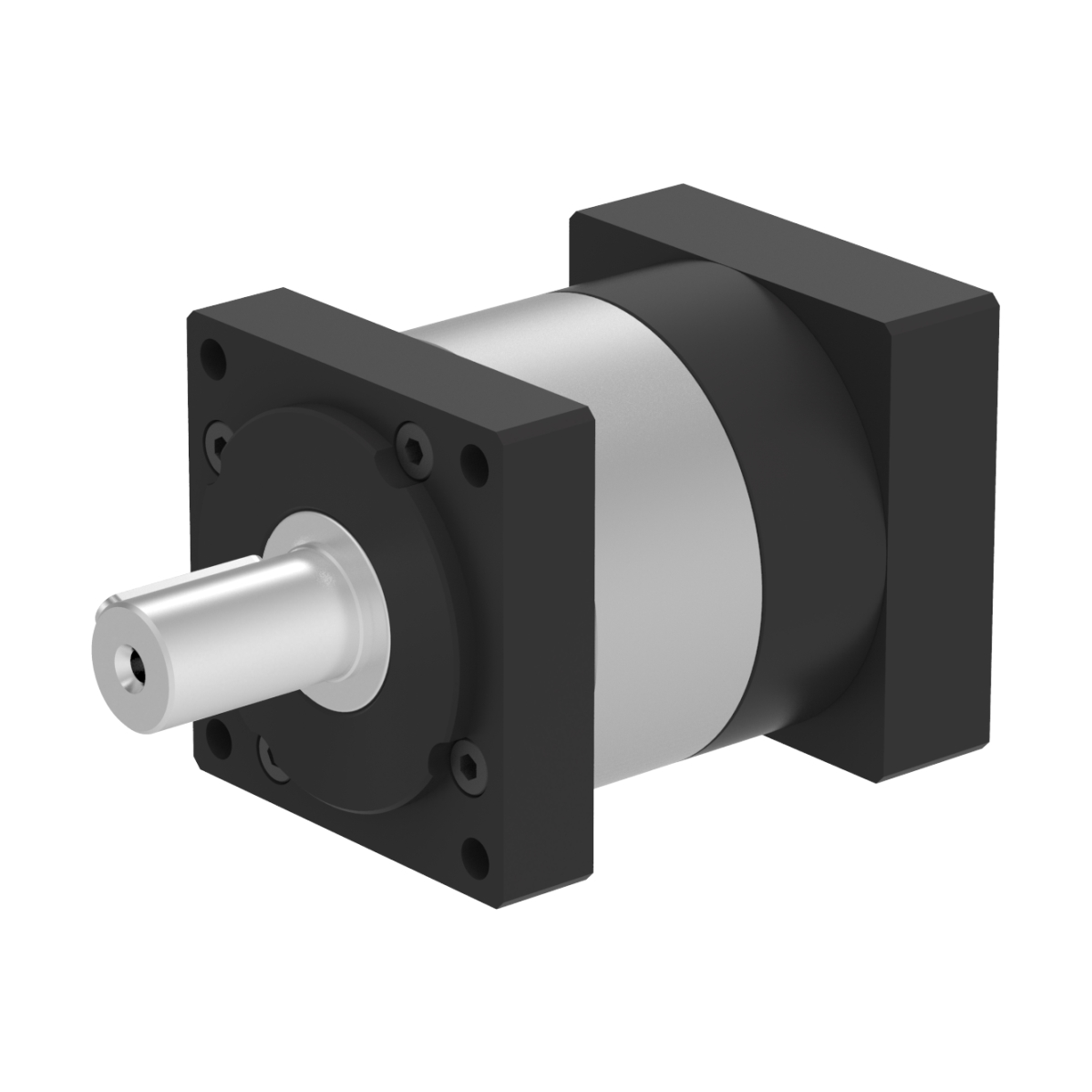

Economy Gear Reducer

The Customized Economy Spur Planetary Gearbox is a project-specific motion transmission solution designed to meet the unique requirements of industrial, automation, and OEM systems. Built on the foundation of proven spur planetary technology, each gearbox is engineered, customized, and optimized for the customer’s specific torque, speed, size, and mounting needs — delivering the ideal balance between performance, cost, and mechanical simplicity. This economical gearbox platform features high-efficiency spur planetary gearing, providing smooth power transmission, compact construction, and high torque density for a wide range of custom machinery and automation applications. Whether integrating into new equipment or upgrading an existing system, it offers flexible design capability and engineering collaboration to ensure optimal performance and long-term reliability.

Standard Precision Gear Reducer

The PS/PN Standard Precision Planetary Gearbox Series is an economical, high-efficiency spur-gear planetary reducer designed for servo, stepper, and general automation applications that require reliable torque transmission and precise motion control. Built on a precision spur planetary architecture, this series offers high mechanical efficiency, compact construction, and strong torque output at an affordable cost. The internal gear train is optimized for accurate positioning, smooth rotation, and long-term durability, making it ideal for both industrial automation and light-duty servo systems.

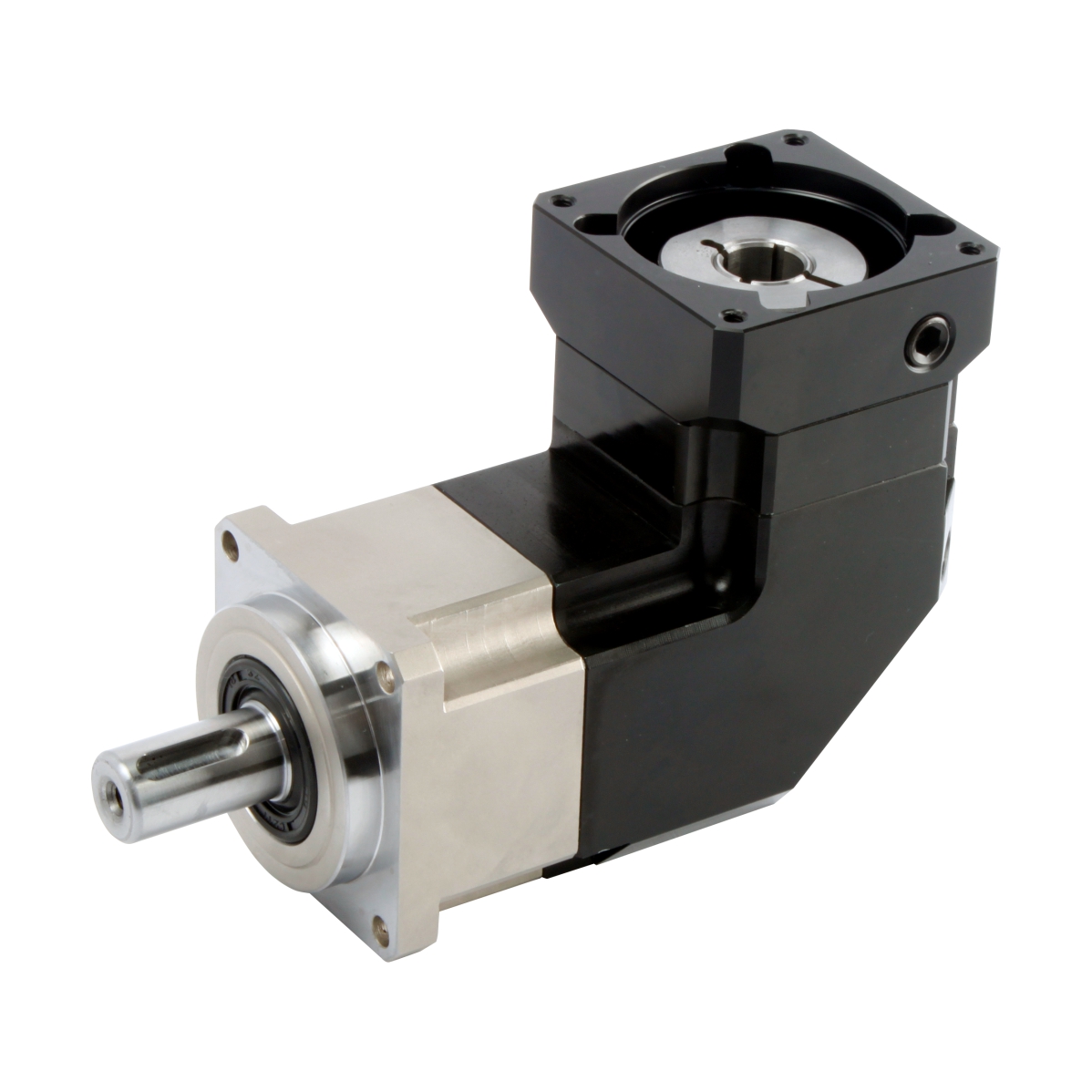

Right Angle Gear Reducer

The RB/RL Series Precision Right Angle Gearbox represents a high-performance solution for servo-driven and automated systems that require compact installation, low backlash, and superior transmission accuracy. Engineered for precise motion control, high torque density, and smooth operation, the RB/RL series integrates spiral bevel gear technology with a planetary reduction stage to deliver outstanding efficiency and alignment stability in space-limited mechanical layouts.

Ultra Precision Gear Reducer

The ZE Series Helical Planetary Gearbox is a cost-effective, high-efficiency helical gear reducer engineered for smooth torque transmission, low noise, and reliable operation in automation, machinery, and general industrial systems. Developed to precision engineering standards, the ZE Series combines the advantages of helical gear design with a compact planetary configuration to achieve higher efficiency, quieter performance, and longer service life than traditional spur-type reducers. Designed for applications requiring excellent torque density and stable motion control at an affordable cost, the ZE Series provides superior performance in servo, stepper, and general motion applications while maintaining an economical structure optimized for system integration.

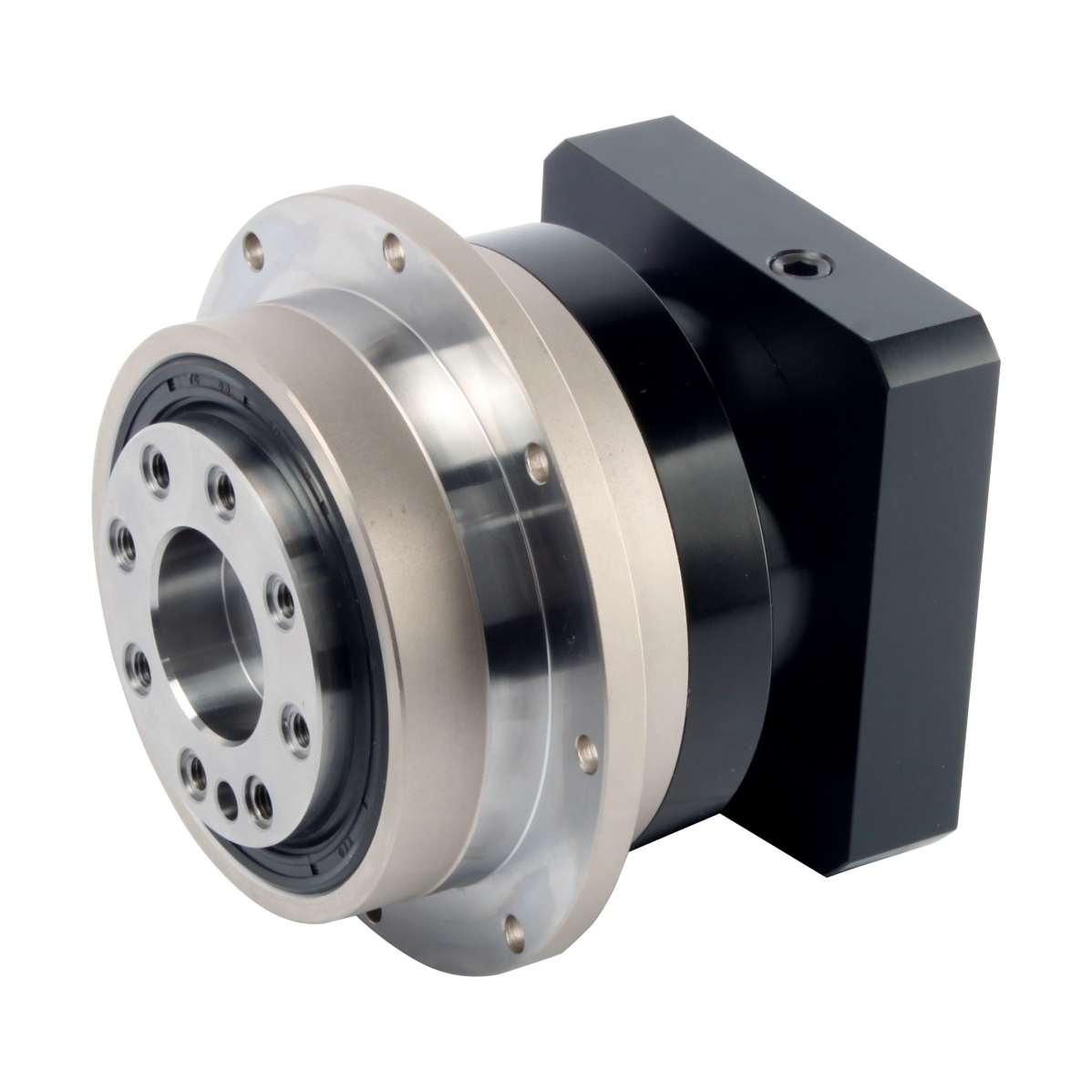

Ultra Precision Gear Reducer

ZF Series Flange output planetary gearbox is a highly efficient and compact mechanical transmission solution that provides precise torque and speed control for various applications. Built with a robust planetary gear system, this gearbox delivers smooth and accurate motion transfer, making it ideal for industries that require high performance, precision, and durability. The flange output design offers a secure and stable connection to the driven machine, ensuring reliable performance even under high loads and dynamic conditions.

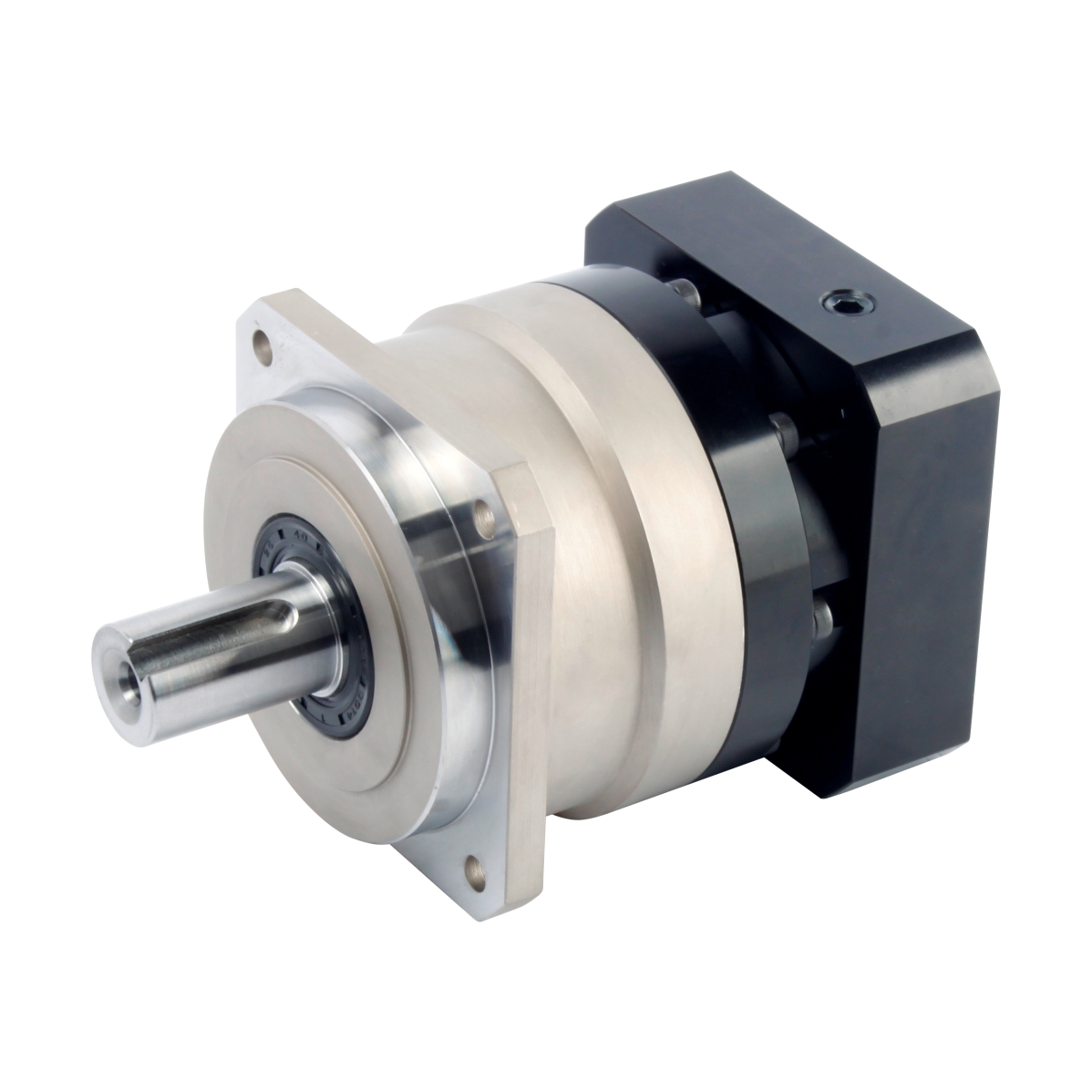

Ultra Precision Gear Reducer

The ZN Series Helical Planetary Gearbox (Round Housing) is a high-precision, low-backlash transmission solution designed for servo-driven automation, robotics, and industrial motion systems. Engineered under advanced design and manufacturing standards, the ZN Series combines helical gear technology with a rigid round housing structure to achieve exceptional efficiency, torque density, and smooth operation within a compact footprint. The precision-ground helical planetary gears offer high transmission accuracy, low noise, and extended operational life, making the ZN Series an ideal choice for both dynamic motion control and continuous-duty industrial applications.

Standard Precision Gear Reducer

The ZP Series spur planetary gear reducer delivers high torque transmission and compact design for a wide range of industrial applications. This reducer uses a spur-gear planetary structure that provides excellent efficiency, smooth rotation, and stable output while maintaining a lightweight, space-saving form. Its precision-machined gears ensure low backlash, consistent performance, and accurate motion control, which is critical for automation systems, robotics, packaging machinery, conveyors, and material handling equipment. The robust housing and high-quality components offer long service life and dependable operation under continuous load, helping reduce maintenance and downtime. The modular design supports multiple ratios and mounting configurations, allowing easy integration into new equipment or existing systems. ZP Series spur planetary gear reducer is ideal for manufacturers and system integrators seeking a cost-effective, reliable, and high-performance gearbox solution that enhances productivity, improves motion control accuracy, and supports modern smart manufacturing requirements.

Right Angle Gear Reducer

The ZRPS / ZRPN Right Angle Gearbox Series represents a high-performance spiral bevel gearbox line, designed for precise torque transmission, compact installation, and long-term reliability in industrial and automation systems. Engineered for smooth power delivery and high efficiency, both models deliver quiet, low-backlash performance with exceptional torque density.

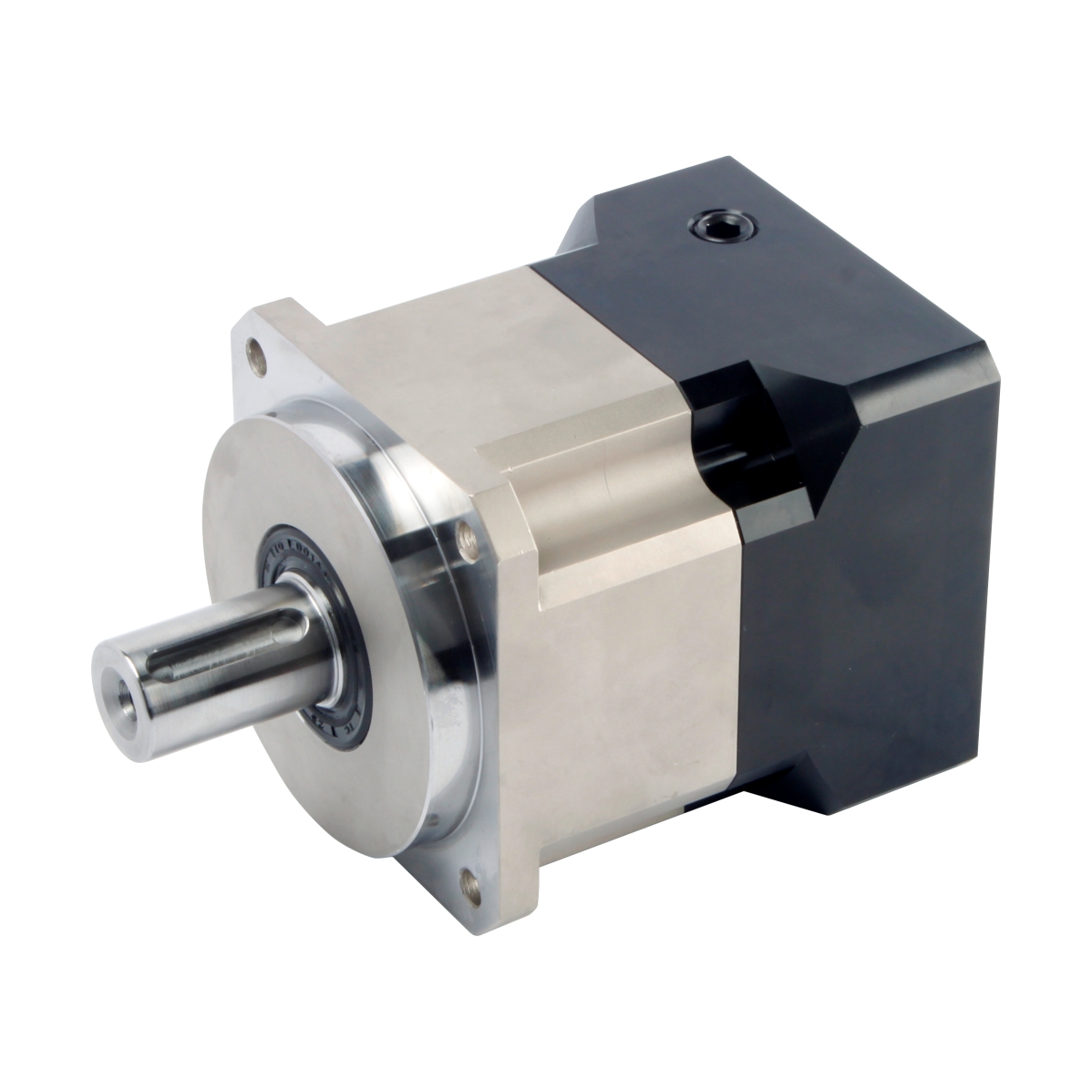

Ultra Precision Gear Reducer

The Square Housing Low Backlash Helical Gear Planetary Gearbox is a precision-engineered transmission solution designed for applications requiring high accuracy, smooth operation, and reliable torque delivery. Its low-backlash helical planetary gears minimize positioning errors, providing excellent repeatability and precise motion control. With a compact square housing, this gearbox is easy to integrate into machinery while offering high torque density and superior load capacity. Ideal for robotics, CNC equipment, automation systems, and high-precision machinery, it delivers the perfect combination of power, accuracy, and durability.

Right Angle Gear Reducer

The ZSR Right Angle Gearbox is a high-performance, compact transmission solution designed for efficient power transfer, torque multiplication, and space-saving mechanical integration. Engineered under precision manufacturing standards, the ZSR series delivers smooth, reliable, and quiet operation for a wide range of industrial and automation applications. Featuring a hardened spiral bevel gear system enclosed within a high-strength aluminum alloy or cast-iron housing, the ZSR Right Angle Gearbox ensures excellent load capacity, low backlash, and a long service life. Its robust design and versatile configuration options make it suitable for both high-speed and heavy-torque applications in modern machinery systems.