ZSB5000 Spring Balancer

The ZSB5000 Spring Balancer is a heavy-duty load-balancing device engineered to provide safe, efficient, and ergonomic handling of heavy tools and equipment in industrial environments. Designed for continuous use in assembly lines, welding stations, and maintenance facilities, the ZSB5000 effectively counterbalances tool weight, allowing operators to move suspended equipment smoothly and effortlessly throughout the work zone. Featuring precision-engineered coil springs, a robust steel housing, and a built-in safety mechanism, the ZSB5000 offers high load capacity, extended service life, and dependable performance under demanding conditions. It is ideal for supporting pneumatic, hydraulic, or electric tools used in repetitive operations — improving both productivity and operator comfort while reducing workplace fatigue.

Key Features

High Load Capacity – Supports tools and equipment up to 50 kg, maintaining stable counterbalance throughout the entire cable travel range.

Adjustable Spring Tension – Allows fine-tuning of balancing force for exact load matching.

Rugged Steel Housing – Heavy-gauge construction ensures durability, shock resistance, and protection in harsh industrial environments.

Precision Steel Wire Cable – Provides smooth retraction, high tensile strength, and long-lasting reliability.

Built-In Safety Device – Automatic lock system prevents sudden tool drop in the event of spring failure.

Sealed Spring Mechanism – Minimizes dust ingress and ensures consistent performance with minimal maintenance.

Smooth Vertical Movement – Enables effortless tool positioning and handling without jerks or rebound.

Easy Mounting and Adjustment – Includes top swivel hook for flexible installation and cable stopper for travel control.

Corrosion-Resistant Finish – Powder-coated surface protects against oxidation, extending the operational lifespan.

Low-Maintenance Design – Enclosed spring housing and sealed bearings provide extended service intervals.

Applications

The ZSB5000 Spring Balancer is ideal for medium to heavy-duty industrial tool handling and assembly tasks, including:

Automotive and truck assembly lines – supporting pneumatic impact wrenches, riveters, and torque multipliers.

Welding and fabrication workstations – balancing MIG/TIG welding guns, grinders, or manipulators.

Machinery maintenance facilities – suspending heavy service tools or calibration instruments.

Aerospace and shipbuilding industries – supporting drilling, riveting, or fastening equipment.

Heavy equipment manufacturing – counterbalancing power tools used for chassis or structural assembly.

Performance Advantages

Ergonomic Operation – Reduces operator fatigue by neutralizing tool weight, allowing one-hand operation.

Enhanced Safety – Internal locking mechanism prevents sudden drops, protecting both users and tools.

High Reliability – Robust spring and cable design withstands repetitive motion over thousands of cycles.

Improved Productivity – Enables smooth and efficient access to tools throughout the entire working area.

Low Maintenance – Factory-sealed lubrication system extends operational life and reduces downtime.

Stable and Balanced Performance – Maintains consistent load positioning for precision assembly and repair work.

Technical Benefits

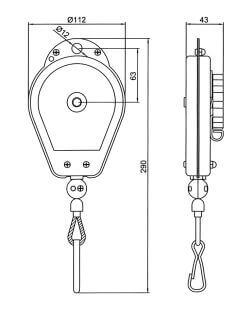

Model: ZSB5000

Load Capacity: 40 – 50 kg (adjustable range)

Cable Travel: Approx. 1.5 – 2.0 meters (depending on setup)

Housing Material: Reinforced steel housing with anti-corrosion finish

Cable Material: Braided stainless steel wire, high tensile grade

Safety Device: Internal ratchet lock with safety latch hook

Spring Type: High-tension coil spring, sealed and pre-lubricated

Mounting Type: Overhead swivel suspension hook or bracket mount

Finish: Industrial-grade powder coating for corrosion resistance

Operating Environment: 0°C to +50°C; indoor industrial use

Maintenance: Minimal; periodic inspection of cable and tension recommended

Why Choose ZSB5000 Spring Balancer

The ZSB5000 Spring Balancer represents commitment to ergonomic innovation, safety, and industrial reliability. Designed for high-load applications, it delivers balanced motion, consistent performance, and rugged durability even in the most demanding production environments. By incorporating the ZSB5000 into your workstation, operators experience reduced fatigue, improved precision, and safer tool handling — key factors in maintaining productivity and workplace safety. Developed under the guiding principles of Power, Precision, and Productivity, the ZSB5000 provides a dependable and maintenance-free lifting solution for heavy-duty assembly tools and equipment across automotive, aerospace, and industrial manufacturing sectors.

Features

- Cost-efficient, practical, and compact. It uses a rotatory Adjusting Cover for more effortless tension adjustment without burden.

- Fast and convenient installation. Additionally, anti-falling steel wire mounting holes are provided, which must be installed to prevent failure at the original mounting location.

- The housing is made of a rustproof iron shell. The steel wires and nylon ropes are available as an option. Furthermore, a ball-shaped damper can also prevent the tool from reaching a fixed height during its recovery stroke.