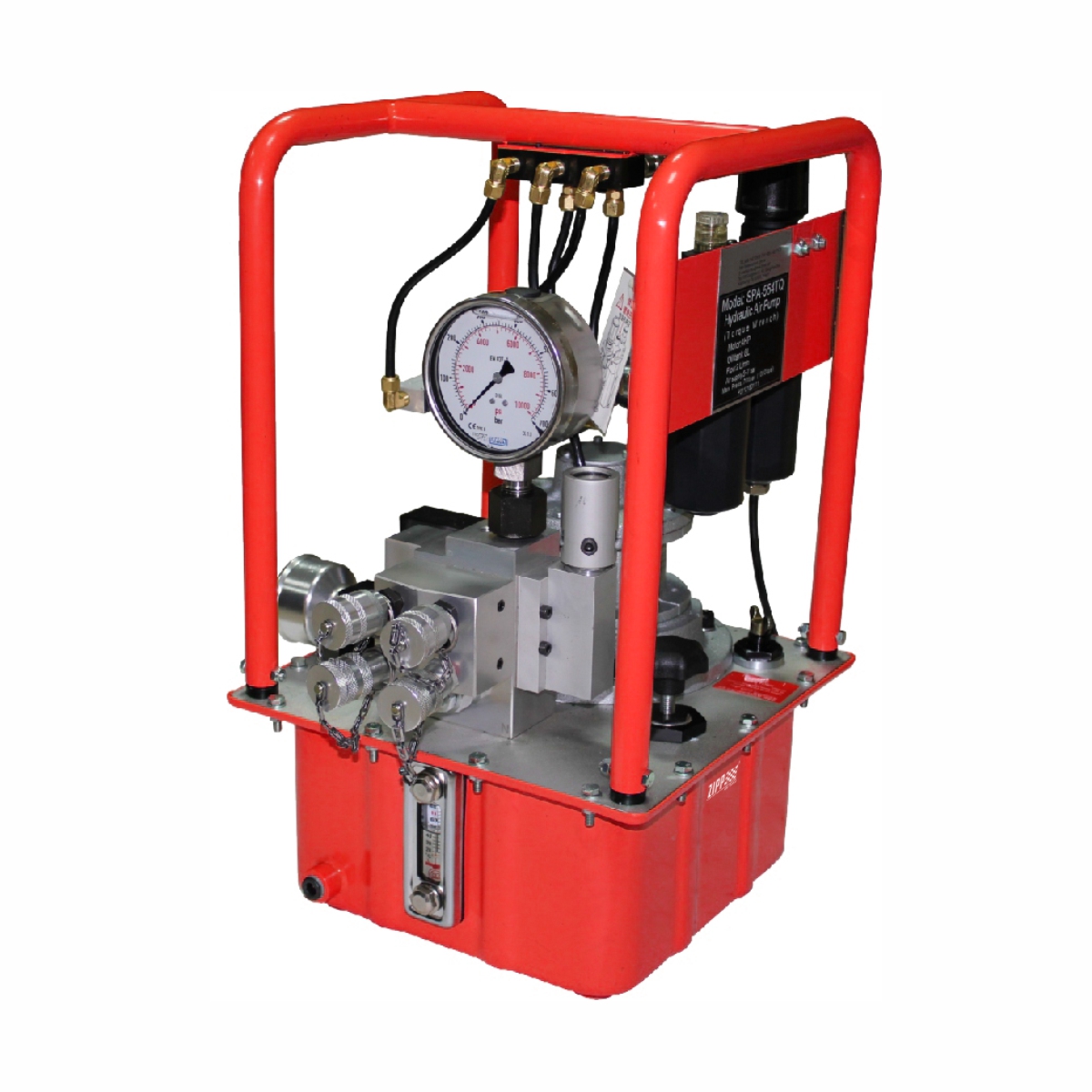

ZSPA-554 Hydraulic Air Pump for Torque Wrench

The ZSPA-554 Hydraulic Air Pump is a high-performance, compact pump designed to power hydraulic torque wrenches in heavy-duty bolting applications. It is ideal for industries requiring precise torque control, including oil and gas, construction, power generation, shipbuilding, and mining. It ensures fast, efficient torque delivery with minimal manual effort, making it essential for bolting operations where accuracy and productivity are critical.

Features

- High Flow Rate: Ensures rapid pressure build-up to reduce cycle times, increasing work efficiency.

- Dual-Stage Pumping System: This system provides a high-flow, low-pressure mode for rapid piston extension and a high-pressure mode for precise torque application.

- Compact and Lightweight Design: Facilitates easy transport and setup, even in remote or confined work areas.

- Pressure Gauge: Large, easy-to-read gauge for accurate pressure monitoring during operation.

- Adjustable Pressure Control: Enables fine-tuning for torque accuracy, ensuring safe and reliable tightening of critical joints.

- Air-Powered Operation: Reduces the risk of overheating and makes the pump ideal for continuous heavy-duty applications.

- Integrated Safety Valve: Protects against overpressure to enhance tool and operator safety.

- Oil Reservoir: Designed with high-capacity hydraulic oil storage, ensuring continuous operation without frequent refilling.

- Anti-Vibration Base: Reduces vibrations for smoother operation and prolongs pump life.

Applications

- Oil & Gas: Flange assembly and maintenance for pipelines and pressure vessels.

- Power Generation: Bolt tightening for turbines, wind energy towers, and transformers.

- Mining and Heavy Machinery: Assembly and maintenance of large excavators, trucks, and processing equipment.

- Shipbuilding and Marine: Ensures precision bolting of hull sections, engines, and propulsion systems.

- Construction: Perfect for bolting structural steel, cranes, and heavy infrastructure.

Key Benefits

- Precise and Reliable Operation: Ensures controlled torque delivery for secure bolting and reduced risk of joint failures.

- Increased Productivity: Faster cycle times with a dual-stage design for rapid operation.

- Portable and Easy to Use: Lightweight construction allows easy transportation between job sites.

- Durable and Safe: Built for harsh environments with safety features to protect operators and equipment.

The ZSPA-554 Hydraulic Air Pump is a critical tool for powering hydraulic torque wrenches. It delivers accurate torque control and efficient performance in demanding applications. Its dual-stage operation, safety features, and portable design make it indispensable for professionals in heavy industries where precision and reliability are paramount.

Hydraulic Air/Torque Wrench Pump

- Powerful four HP motor starts under load.

- Use where air is the preferred source of power.

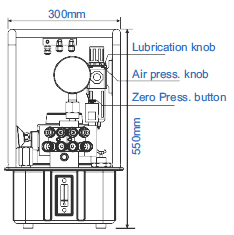

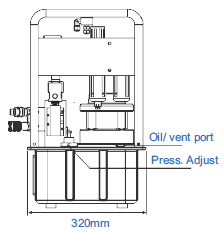

- Max. Pressure: 700bar

- Two-speed high-performance pump.

- External adjustable pressure regulator.

- The retract side internal relief valve protects the tool.

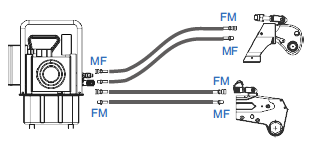

- Opt for eight 1/4″ ports (including female and male couplers with dust caps) synchronizing work for four hydraulic wrenches.

- Use for Hydraulic Torque Wrench

- Pneumatic remote control with 5M cord.

Optional

G= Pressure Gauge

ZSPA554TQ-A-A1

Pneumatic remote

| Model Number |

Air Supply Req’d |

rpm | dB(A) at Idle and 700bar | Motor | Flow rate (l/min) | oil tank | Weight with oil |

|||

| hp | 0(bar) | 70(bar) | 350(bar) | 700(bar) | L | kg | ||||

| ZSPE-554 | 1.4M³/min @6 bar | 3000 | 75 | 4 | 74 | 1.3 | 1.1 | 0.9 | 8 | 38.5 |

Torque Wrench Hoses:

Use ZIPP ZXU22W series torque wrench hoses with every model torque wrench to ensure the integrity of your

hydraulic system.

| Model Number | Tube Dia. | Length | Motor | W.P | B.P | ||

| inch | ft | m | inch | bar | bar | ||

| ZXU22W-6M2NM2NM | 1/4 | 20 | 6 | 1/4 | 1/4 | 700 | 2800 |

| ZXU22W-12M2NM2NM | 1/4 | 40 | 12 | 1/4 | 1/4 | 700 | 2800 |

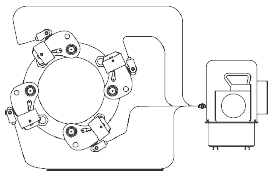

Basic System Set-up

A. 1 Hydraulic Torque Wrench using Electric Pump +1 Square Drive Wrench +Socket +2 hoses

B. 1 Hydraulic Torque Wrench using Electric Pump +1 Low Profile Wrench +2 hoses

C. 1 Hydraulic Torque Wrench using Electric Pump +1~4 Square Drive Wrench (+Socket) or 1~4 Low Profile Wrench +2~8 hoses

Wrench Torque Formula

T = F x r

Torque = Force x Lever Arm Length

Ex.: 1000kN x 60mm= 60000 N.m

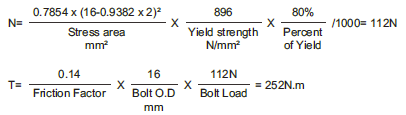

Bolt Load- Torque Formula

T = K x D x N

T: Torque

K: Friction Factor

D: Bolt O.D

N: Bolt extended Load = Stress area x Yield strength x Percent of Yield

Ex.: M16

μ= 0.10: Low friction application

μ= 0.15: Normal friction application

μ= 0.20: High friction application

| Bolt grade | Tension strength |

Yield strength(90%) |

Tightening moment | ||||||||

| RM(N/mm²) | Rp0.2(N/mm²) | N.m | |||||||||

| 6.8 | 600 | 480 | μ= 0.1 | 110 | 160 | 220 | 300 | 390 | 570 | 770 | 1050 |

| μ= 0.15 | 150 | 200 | 290 | 400 | 500 | 740 | 1000 | 1370 | |||

| μ= 0.2 | 170 | 240 | 340 | 460 | 590 | 870 | 1180 | 1610 | |||

| 8.8 | 80 | 640 | μ= 0.1 | 150 | 210 | 300 | 410 | 520 | 760 | 1030 | 1400 |

| μ= 0.15 | 200 | 270 | 390 | 530 | 670 | 990 | 1340 | 1820 | |||

| μ= 0.2 | 230 | 320 | 450 | 630 | 780 | 1160 | 1570 | 2140 | |||

| B.7 (≤2-1/2″) |

min. 860 |

min. 720 |

μ= 0.1 | 180 | 250 | 350 | 470 | 600 | 880 | 1190 | 1610 |

| μ= 0.15 | 230 | 320 | 450 | 610 | 770 | 1140 | 1550 | 2100 | |||

| μ= 0.2 | 270 | 370 | 530 | 720 | 910 | 1340 | 1820 | 2480 | |||

| 10.9 | 1000 | 900 | μ= 0.1 | 220 | 310 | 440 | 600 | 760 | 1110 | 1510 | 2050 |

| μ= 0.15 | 290 | 400 | 570 | 780 | 980 | 1450 | 1970 | 2680 | |||

| μ= 0.2 | 340 | 470 | 670 | 920 | 1150 | 1710 | 2310 | 3150 | |||

| 12.9 | 1200 | 1080 | μ= 0.1 | 260 | 370 | 510 | 700 | 890 | 1300 | 1770 | 2400 |

| μ= 0.15 | 340 | 470 | 670 | 920 | 1150 | 1700 | 2300 | 3130 | |||

| μ= 0.2 | 400 | 550 | 780 | 1080 | 1340 | 2000 | 2700 | 3680 | |||

| M | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | |||

| Bolt grade | Tension strength |

Yield strength(90%) |

Tightening moment |

|||||||

| RM(N/mm²) | Rp0.2(N/mm²) | N.m |

||||||||

| 6.8 | 600 | 480 | μ= 0.1 | 1350 | 1740 | 2160 | 2690 | 3250 | 4180 | 5190 |

| μ= 0.15 | 1760 | 2280 | 2820 | 3530 | 4250 | 5490 | 6800 | |||

| μ= 0.2 | 2060 | 2690 | 3320 | 4160 | 5000 | 6470 | 8020 | |||

| 8.8 | 80 | 640 | μ= 0.1 | 1790 | 2320 | 2880 | 3590 | 4330 | 5570 | 6920 |

| μ= 0.15 | 2340 | 3040 | 3760 | 4170 | 5660 | 7320 | 9070 | |||

| μ= 0.2 | 2750 | 3580 | 4430 | 5550 | 6670 | 8630 | 10700 | |||

| B.7 (≤2-1/2″) |

min. 860 |

min. 720 |

μ= 0.1 | 2080 | 2690 | 3330 | 4150 | 5010 | 6440 | 8000 |

| μ= 0.15 | 2700 | 3520 | 4350 | 5450 | 6550 | 8450 | 10490 | |||

| μ= 0.2 | 3180 | 4140 | 5120 | 6420 | 7710 | 9980 | 12370 | |||

| 10.9 | 1000 | 900 | μ= 0.1 | 2640 | 3410 | 4230 | 5280 | 6360 | 8180 | 10160 |

| μ= 0.15 | 3430 | 4460 | 5530 | 6920 | 8320 | 10740 | 13330 | |||

| μ= 0.2 | 4040 | 5260 | 6500 | 8150 | 9790 | 12670 | 15710 | |||

| 12.9 | 1200 | 1080 | μ= 0.1 | 3080 | 3990 | 4950 | 6170 | 7440 | 9570 | 11890 |

| μ= 0.15 | 4020 | 5220 | 6470 | 8090 | 9740 | 12570 | 15590 | |||

| μ= 0.2 | 4720 | 6150 | 7610 | 9540 | 11460 | 14830 | 18380 | |||

| M | 36 | 39 | 42 | 45 | 48 | 52 | 56 | |||

| Bolt grade | Tension strength |

Yield strength(90%) |

Tightening moment |

|||||||

| RM(N/mm²) | Rp0.2(N/mm²) | N.m |

||||||||

| 6.8 | 600 | 480 | μ= 0.1 | 6440 | 7320 | 8520 | 9920 | 10170 | 10460 | 11720 |

| μ= 0.15 | 8480 | 9630 | 11230 | 13100 | 13470 | 13880 | 15580 | |||

| μ= 0.2 | 10010 | 11350 | 13270 | 15510 | 15960 | 16460 | 18510 | |||

| 8.8 | 80 | 640 | μ= 0.1 | 8590 | 9760 | 11360 | 13220 | 13560 | 13950 | 15620 |

| μ= 0.15 | 11300 | 12830 | 14970 | 17470 | 17960 | 18510 | 20780 | |||

| μ= 0.2 | 13350 | 15140 | 17690 | 10680 | 21280 | 21950 | 24670 | |||

| B.7 (≤2-1/2″) |

min. 860 |

min. 720 |

μ= 0.1 | 9930 | 11280 | 13130 | 15290 | 15680 | 16130 | 18060 |

| μ= 0.15 | 13060 | 14830 | 17310 | 20200 | 20770 | 21400 | 24020 | |||

| μ= 0.2 | 15430 | 17500 | 20460 | 23910 | 24610 | 25380 | 28530 | |||

| 10.9 | 1000 | 900 | μ= 0.1 | 12610 | 14330 | 16680 | 19420 | 19920 | ||

| μ= 0.15 | 16600 | 18840 | 21990 | 25660 | 26380 | |||||

| μ= 0.2 | 19600 | 22240 | 25990 | 30370 | 31260 | |||||

| 12.9 | 1200 | 1080 | μ= 0.1 | 14760 | 16770 | 19520 | ||||

| μ= 0.15 | 19430 | 22050 | 25730 | |||||||

| μ= 0.2 | 22940 | 26020 | 30410 | |||||||

| M | 60 | 64 | 68 | 72 | 76 | 80 | 85 | |||

| Bolt grade | Tension strength |

Yield strength(90%) |

Tightening moment |

|||||||

| RM(N/mm²) | Rp0.2(N/mm²) | N.m |

||||||||

| 6.8 | 600 | 480 | μ= 0.1 | 13250 | 14690 | 16540 | 19650 | 20900 | 23780 | 25570 |

| μ= 0.15 | 17660 | 19620 | 22130 | 26360 | 28080 | 31980 | 34430 | |||

| μ= 0.2 | 21000 | 23350 | 26370 | 31450 | 33530 | 38210 | 41160 | |||

| 8.8 | 80 | 640 | μ= 0.1 | 17670 | 19590 | 22060 | 26200 | |||

| μ= 0.15 | 23550 | 26160 | 29510 | 35150 | ||||||

| μ= 0.2 | 28000 | 31140 | 35150 | 41930 | ||||||

| B.7 (≤2-1/2″) |

min. 860 |

min. 720 |

μ= 0.1 | 20430 | 22650 | 25510 | ||||

| μ= 0.15 | 27250 | 30250 | 34120 | |||||||

| μ= 0.2 | 32380 | 36000 | 40650 | |||||||

| 10.9 | 1000 | 900 | μ= 0.1 | |||||||

| μ= 0.15 | ||||||||||

| μ= 0.2 | ||||||||||

| 12.9 | 1200 | 1080 | μ= 0.1 | |||||||

| μ= 0.15 | ||||||||||

| μ= 0.2 | ||||||||||

| M | 90 | 95 | 100 | 110 | 115 | 120 | 125 | |||

Nominal thread size [mm]

The data above is based on bolts lubricated to the manufacturer’s specifications.

Due to a variation in friction, we recommend checking with the bolt manufacturer in extreme cases, as this chart represents a guideline only.