ZRS2508ED Air Rivet Stud Tool – With Digital Module

FOR IMPERIAL SYSTEM

The ZRS2508ED Air Rivet Stud Tool with Digital Module is a high-performance, technologically advanced tool for precision fastening in industrial applications. Featuring a digital module for enhanced control and monitoring, this tool combines pneumatic power with digital intelligence to provide real-time data tracking, increased accuracy, and productivity in demanding settings. It is particularly suited for industries where precision and traceability of rivet installations are paramount.

Key Features

- Integrated Digital Module: This module displays critical installation data, allowing operators to monitor fastening metrics in real time, enhancing control and reducing errors.

- Air-Powered Efficiency: Uses a powerful pneumatic drive for consistent performance, making it suitable for high-volume applications.

- Precision Control: The digital interface improves accuracy by allowing adjustments to ensure uniform and secure fastening.

- Durable and Ergonomic Design: It’s built from high-strength materials to withstand rigorous use while offering a comfortable grip for ease of handling.

- Quick Maintenance and Serviceability: Streamlined access for servicing, minimizing downtime and ensuring uninterrupted operation.

Applications

- Automotive Manufacturing: Ideal for precise stud installation in assembly lines where traceability and high productivity are essential.

- Aerospace and Aviation: Ensures accuracy and traceable records for rivet installation in aircraft manufacturing and maintenance.

- Industrial Manufacturing: Supports fast and precise riveting in metal fabrication, electronic assembly, and heavy machinery.

- Quality-Controlled Assembly Environments: The digital module’s data tracking is valuable for applications requiring consistent quality and compliance documentation.

Benefits

- Enhanced Productivity: Pneumatic power paired with digital accuracy accelerates work cycles, improving efficiency on production lines.

- Data-Driven Quality Control: Real-time feedback allows operators to verify each installation, reducing rework and ensuring consistent assembly standards.

- Reduced Operator Fatigue: Ergonomic build and intuitive digital interface make extended use more comfortable, helping operators maintain productivity.

- Long-Term Cost Savings: Durable construction and easy serviceability reduce replacement needs, making it a cost-effective choice.

The ZRS2508ED Air Rivet Stud Tool with Digital Module is a comprehensive solution for applications demanding speed, accuracy, and traceability. This tool is an asset in any precision-driven environment where digital control and data capture are critical to meeting production and quality goals.

Features

- It features the most advanced patented digital module, enabling operators to know the rivet tool setting capacity instantly under various air supply conditions and the rivet setting cycles performed during their working period.

- It will also remind operators when to do service or maintenance to the tool at proper intervals.

- It will help to cease the controversy about warranty issues, especially if the tool has been misused or abused with abnormally high air pressure that exceeds the design specification.

- It is built with patented “Module units assembled in composite clam shell housing” for ease of tool service.

- Forged and heat-treated aluminum alloy made Hydraulic Section for the best rigidity.

- Easy adjustable Head & Nut designed for obtaining the most effective stroke.

- Ergonomic texture-coated composite housing for operator’s comfort.

- Swivel air inlet design for maneuverability works.

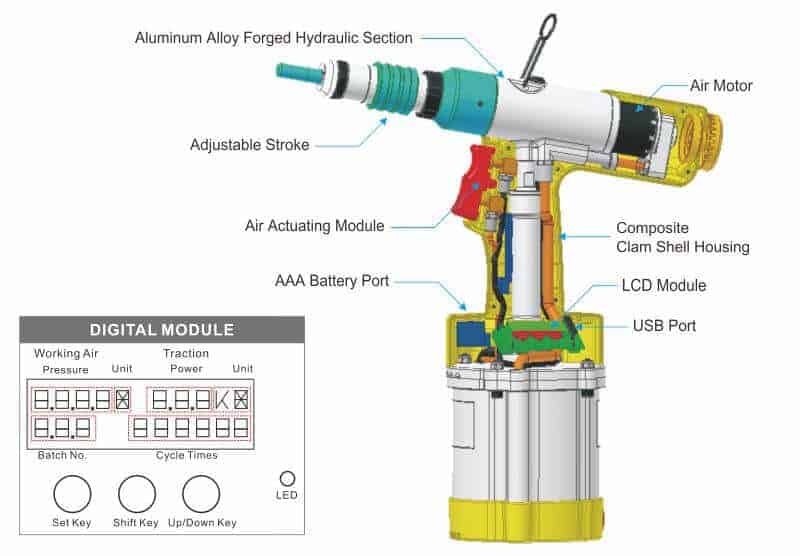

- Aluminum Alloy Forged Hydraulic Section

- Adjustable Stroke

- Air Motor

- Air Actuating Module

- Composite Clam Shell Housing

- AAA Battery Port

- LCD Module

- USB Port

Specification:

- Traction Power: 5500(2500) Ibf(kgf)

- Stroke Length: 8 mm

- Net Weight: 5.4(2.4) lbs(kgs)

- Rivet Nut / Rivet Stud Setting Capacity: #8-32~3/8″-16 rivet stud in all materials

DO NOT apply air pressure over 110 psi / 7.5 bar to these tools.

*Please refer to the blind rivet specification to ensure the tensile strength is lower than the traction power of your selected model.

| Model | Traction Power lbf(kgf) | Stroke Length inch(mm) | Net Weight lbs(kgs) | Rivet Nut / Rivet Stud Setting Capacity |

| ZRN1606E | 3500(1600) | 1/4(6) | 4.9(2.2) | #8-32~3/8″-16 rivet nut in Hex./Steel 1/2″-13 need 100psi/7 bar operating pressure |

| ZRN1606ED | 3500(1600) | 1/4(6) | 4.9(2.2) | #8-32~3/8″-16 rivet nut in Hex./Steel 1/2″-13 need 100psi/7 bar operating pressure |

| ZRN1606M | 3500(1600) | 1/4(6) | 4.9(2.2) | M4~M10 rivet nut in Hex./Steel M12 needs 100psi/7 bar operating pressure |

| ZRN1606MD | 3500(1600) | 1/4(6) | 4.9(2.2) | M4~M10 rivet nut in Hex./Steel M12 needs 100psi/7 bar operating pressure |

| ZRN2508E | 5500(2500) | 5/16(8) | 5.4(2.4) | #8-32~1/2″-13 rivet nut in all materials |

| ZRN2508ED | 5500(2500) | 5/16(8) | 5.4(2.4) | #8-32~1/2″-13 rivet nut in all materials |

| ZRN2508M | 5500(2500) | 5/16(8) | 5.4(2.4) | M4~M12 rivet nut in all materials |

| ZRN2508MD | 5500(2500) | 5/16(8) | 5.4(2.4) | M4~M12 rivet nut in all materials |

| ZRS1606E | 3500(1600) | 1/4(6) | 4.9(2.2) | #8-32~3/8″-16 rivet stud in all materials |

| ZRS1606ED | 3500(1600) | 1/4(6) | 4.9(2.2) | #8-32~3/8″-16 rivet stud in all materials |

| ZRS1606M | 3500(1600) | 1/4(6) | 4.9(2.2) | M4~M10 rivet stud in all materials |

| ZRS1606MD | 3500(1600) | 1/4(6) | 4.9(2.2) | M4~M10 rivet stud in all materials |

| ZRS2508E | 5500(2500) | 5/16(8) | 5.4(2.4) | #8-32~3/8″-16 rivet stud in all materials |

| ZRS2508ED | 5500(2500) | 5/16(8) | 5.4(2.4) | #8-32~3/8″-16 rivet stud in all materials |

| ZRS2508M | 5500(2500) | 5/16(8) | 5.4(2.4) | M4~M10 rivet stud in all materials |

| ZRS2508MD | 5500(2500) | 5/16(8) | 5.4(2.4) | M4~M10 rivet stud in all materials |